Air Shower

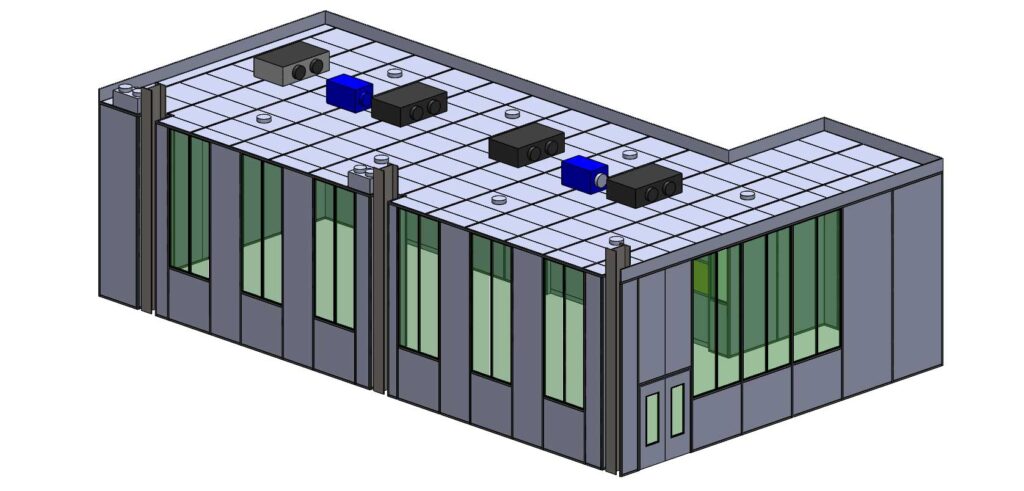

Kipril, Your Trusted China Cleanroom Supplier

Specializing in modular cleanroom and pre-fabricated cleanroom, Kipril delivers ISO class 3 to ISO class 8 certificated, turnkey cleanroom solutions with full on-site installation and commissioning. From design to production, scalable, precise and reliable.

Air Showers Manufacturer

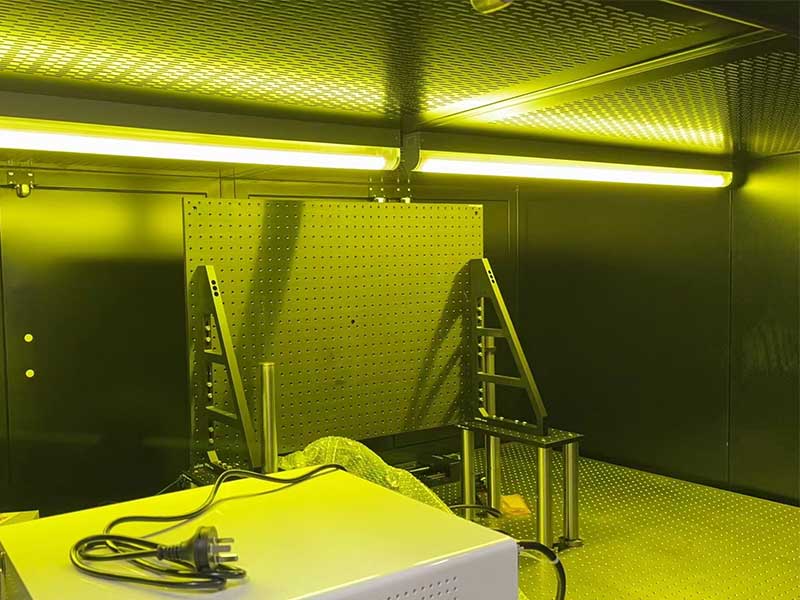

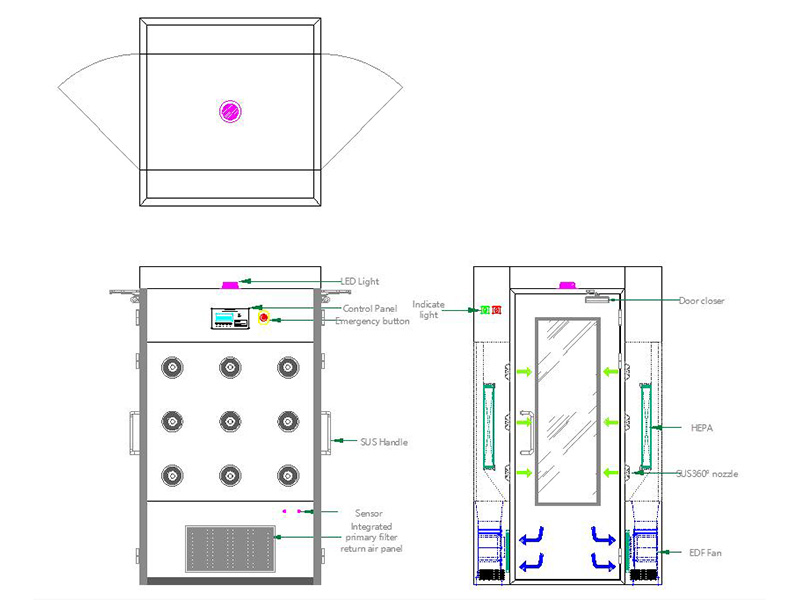

The Air Shower is a purification device used for personnel or materials before entering clean areas. Through high-speed clean airflow blow-off, it effectively removes dust particles attached to personnel or objects, serving as a crucial barrier device for maintaining cleanroom environments.

Core Features:

High-Efficiency Purification

- Multi-angle high-speed airflow (20-25m/s wind speed)

- ≥99.9% removal efficiency (for particles ≥0.5μm)

- Dual-door interlock system prevents cross-contamination

Intelligent Control System

- Automatic induction blow-off (infrared/photoelectric sensor)

- Adjustable blow-off time (10-99 seconds configurable)

- Differential pressure monitoring and alarm function

- Touchscreen HMI interface

Premium Structural Design

- 304 stainless steel or high-quality cold-rolled steel cabinet

- Double-layer sealed door structure

- Anti-static grounding device

- Low-noise design (≤65dB)

Energy Saving & Eco-Friendly

- High-efficiency centrifugal fan

- Auto standby function

- Low energy consumption design

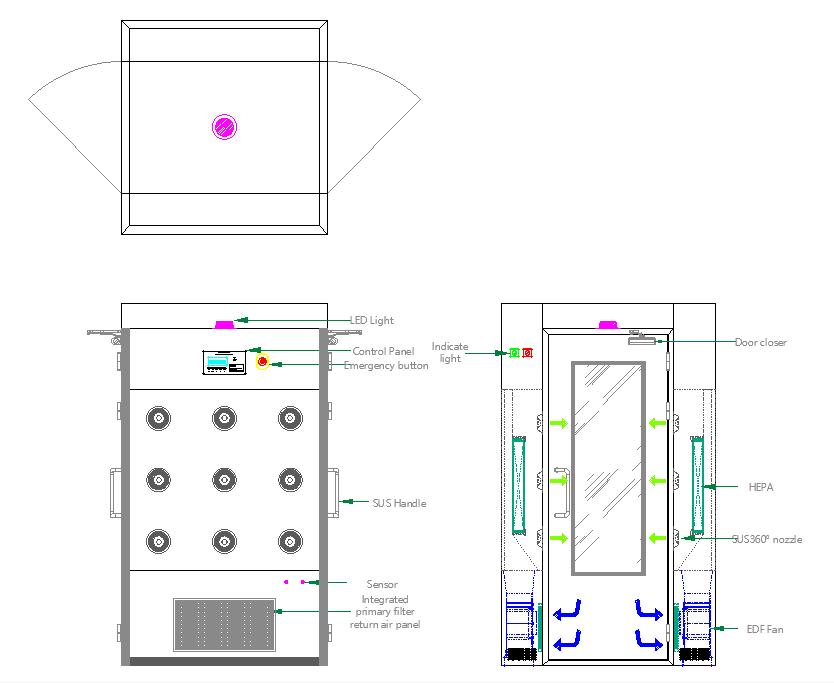

Details of the parts used for Airshower

KipRil Blog

Revolutionizing Clean Room Technology: The Emergence of Intelligent Air Shower Rooms

The Evolution of Intelligent Air Shower Rooms In the rapidly...

Read MoreGet in Touch

Send your enquiry and we will reply you in the first time.

Get in touch with us!

What is an Air Shower?

An air shower is a self-contained system commonly installed at the entrance to cleanrooms or other dust-controlled environments. Before personnel, raw materials, or equipment enter these sensitive spaces, they must pass through the air shower, which removes dust, debris, and particles.

A typical air shower includes pre-filters, HEPA filters, corrugated fans, high-velocity nozzles, timers, sensors, and interlocked doors. It delivers high-speed clean air (usually from 25 to 60 seconds) to ensure contaminants are removed. This setup is essential in fields like semiconductors, pharmaceuticals, laboratories, optics, and hydrogen manufacturing.

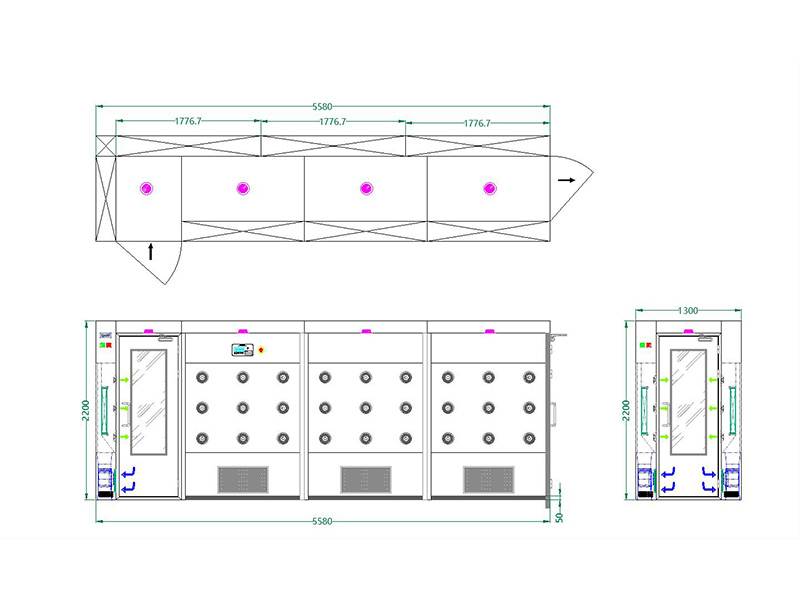

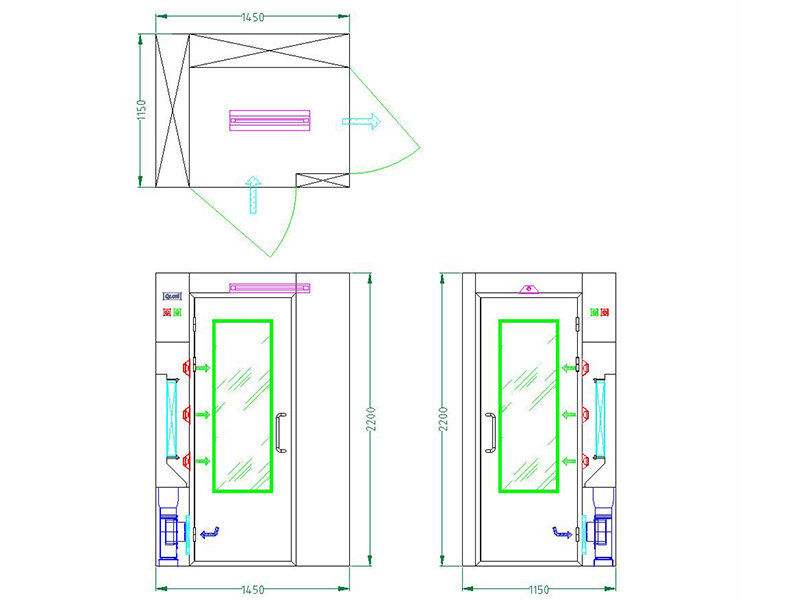

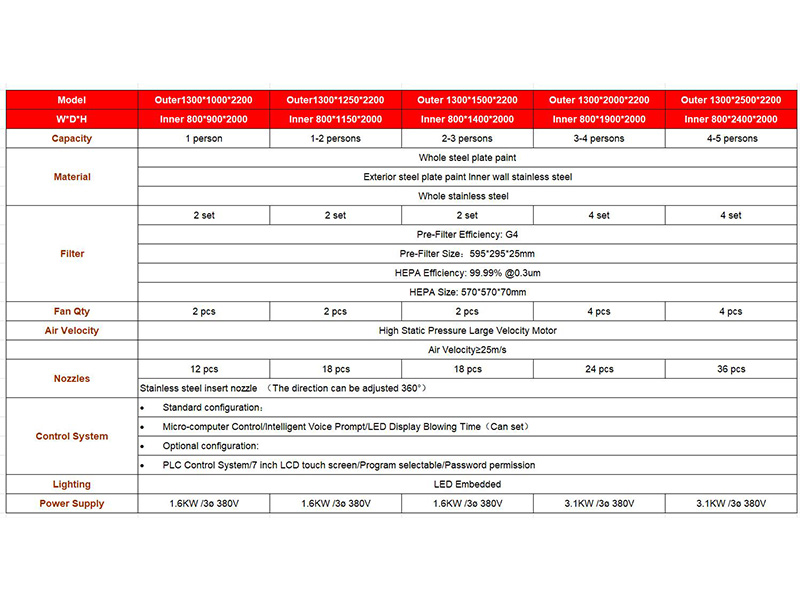

Different models exist: single-person, tunnel-type, or L-shaped air showers depending on space and usage needs. A qualified air shower manufacturer will offer all these configurations and assist with selection.

Why Use an Air Shower?

Contamination control is critical. Regulatory bodies like ISO 14644, GMP, and FDA require such systems. For example, ISO 14644-5, article 4.5.2 mandates that procedures must be in place to avoid contaminating cleanroom materials or equipment.

Acting as a barrier system, the air shower eliminates dust particles from individuals or materials, prolonging the life of internal HEPA/ULPA filters and reducing cleanroom maintenance costs.

More than just a physical barrier, the air shower serves as a behavioral reminder to gown properly and follow hygiene protocols. Cleanroom managers may display gowning guidelines beside the air shower system to reinforce compliance.

A knowledgeable air shower manufacturer will help configure the air shower as both a technical and procedural checkpoint.

How to Choose the Right Air Shower?

Step 1: Define the application – is it for personnel, material, or mixed use?

Step 2: Determine user flow rate and largest material size to select the proper air shower size (single, tunnel, etc.).

Step 3: Consider plant layout. Choose from straight-through, L-shape, U-shape, or custom configurations.

Step 4: Check cleanroom classification. ISO 5 or cleaner may require airlocks in addition to air showers.

Step 5: Evaluate air speed and cycle time – ideal nozzle velocity is 20–30 m/s, adjustable from 10–60 seconds.

Step 6: Choose materials – stainless steel for clean-critical industries, or powder-coated steel for economical solutions.

Step 7: Verify certifications (e.g. CE/UL) and comply with local HSE regulations.

[More on cleanroom classifications]

What Air Shower Models Does Kipril Offer?

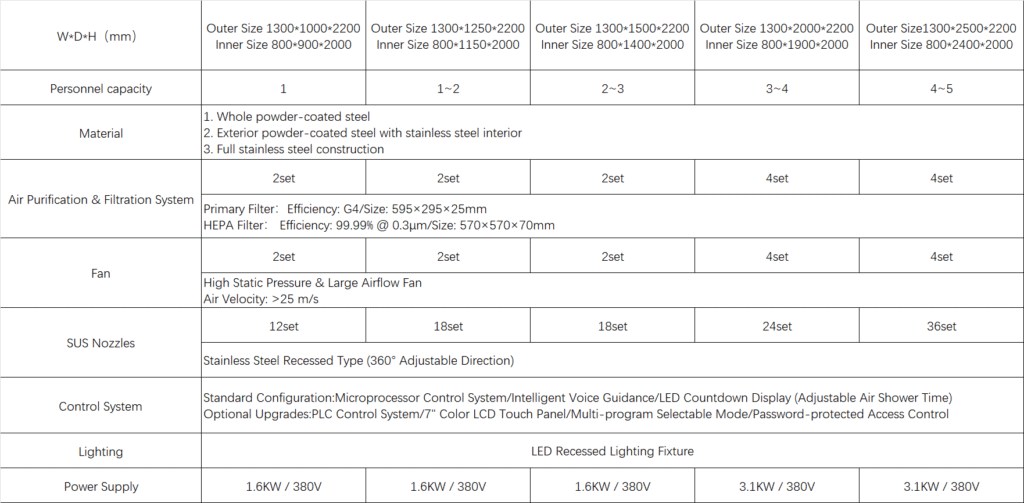

Kipril is a trusted air shower manufacturer offering OEM/ODM solutions. Below is a table summarizing their most popular models:

How to Ship, Install, and Commission an Air Shower?

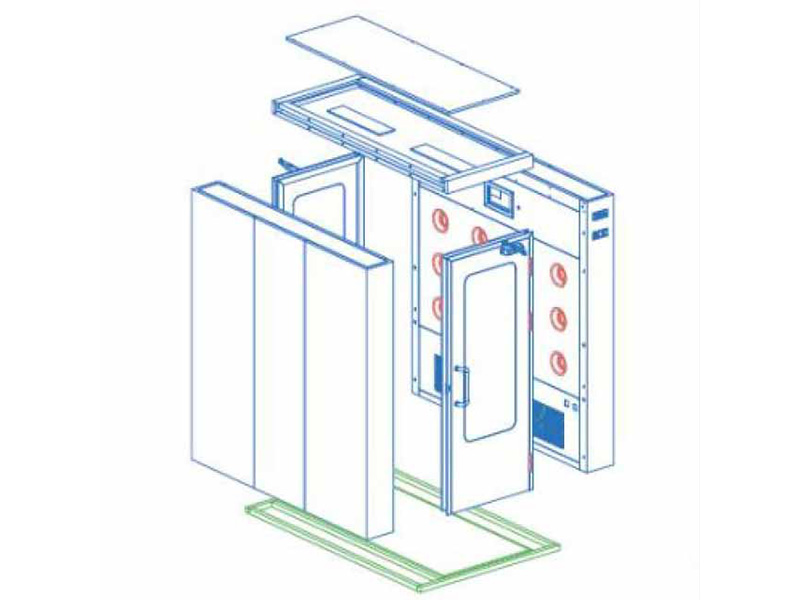

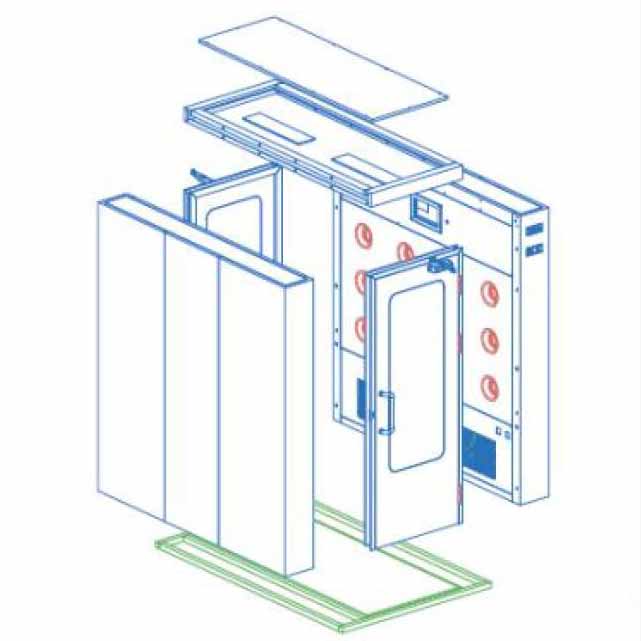

Once assembled and quality-checked, air showers are packed and shipped in one of two ways:

1. Fully Assembled: Wrapped in protective film, secured in a wooden crate or pallet. Ready to install – faster but more expensive shipping.

2. Disassembled (modular): Frames, filters, and components separated. Cost-effective for overseas clients with flexible site timelines.

Each shipment includes a manual, compliance certificate, packing list, and electrical drawings.

Commissioning steps: test fans, lights, interlocks, HEPA filter integrity, nozzle airspeed, door operations, sensors, emergency stop, RFID if applicable, and final cleaning.

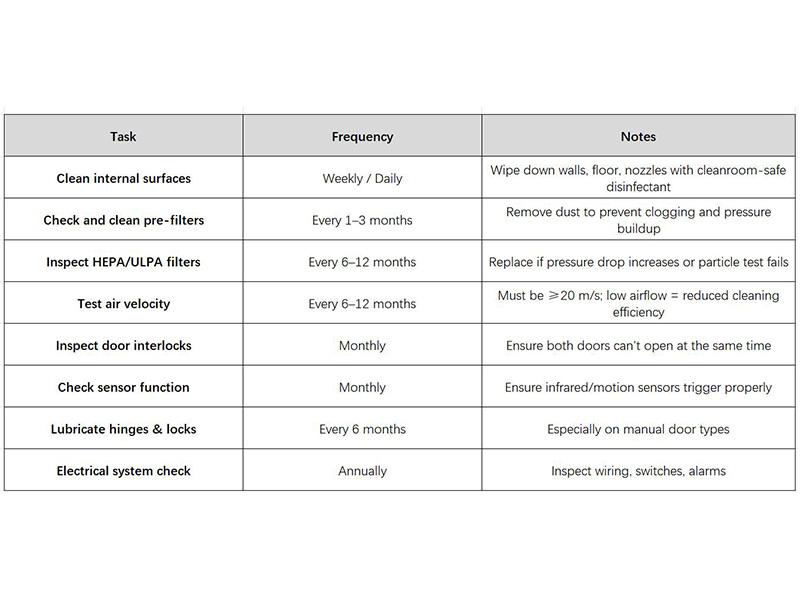

Does an Air Shower Require Maintenance?

Yes! Like all cleanroom equipment, air showers require regular maintenance to ensure performance and protect cleanroom integrity.

A proactive air shower manufacturer will offer maintenance contracts or checklists.

Warning Signs: weak/no airflow, loud blower noise, doors stuck or open together, dust in air shower, staff avoiding the system.

Does HEPA Need to Be Changed? What is the Frequency?

Absolutely. HEPA filters, being a critical component of the air shower, must be regularly maintained to ensure optimal filtration efficiency and protect the cleanroom environment. Over time, HEPA filters trap increasing amounts of particles, which leads to pressure drop and reduced airflow.

A clogged or saturated HEPA filter can compromise the air shower’s ability to remove contaminants effectively. Therefore, it’s essential to monitor the differential pressure across the filter or perform periodic particle count tests.

As a general guideline, HEPA filters should be inspected every 6 to 12 months, depending on the level of usage and cleanroom classification. If there is a noticeable pressure increase or failure in efficiency tests, the filters should be replaced immediately.

A reliable air shower manufacturer will often offer HEPA filter life estimation, monitoring systems, and replacement services to ensure uninterrupted cleanroom performance.