Modular Cleanroom

Kipril, Your Trusted China Cleanroom Supplier

Specializing in modular cleanroom and pre-fabricated cleanroom, Kipril delivers ISO class 3 to ISO class 8 certificated, turnkey cleanroom solutions with full on-site installation and commissioning. From design to production, scalable, precise and reliable.

Modular Cleanroom Manufacturer

Modular Cleanroom – Prefabricated Efficient Solution

Unlike traditional cleanrooms that require on-site construction using raw materials like tubes and wall panels, modular cleanrooms adopt a prefabricated assembly approach, featuring faster deployment, higher efficiency, and better cost-effectiveness.

After years of continuous improvement, modular cleanrooms have become the ideal choice for rapid deployment in industries including:

Food processing

Semiconductor manufacturing

Pharmaceutical laboratories

Chemical production

New energy and battery manufacturing

Key Advantages

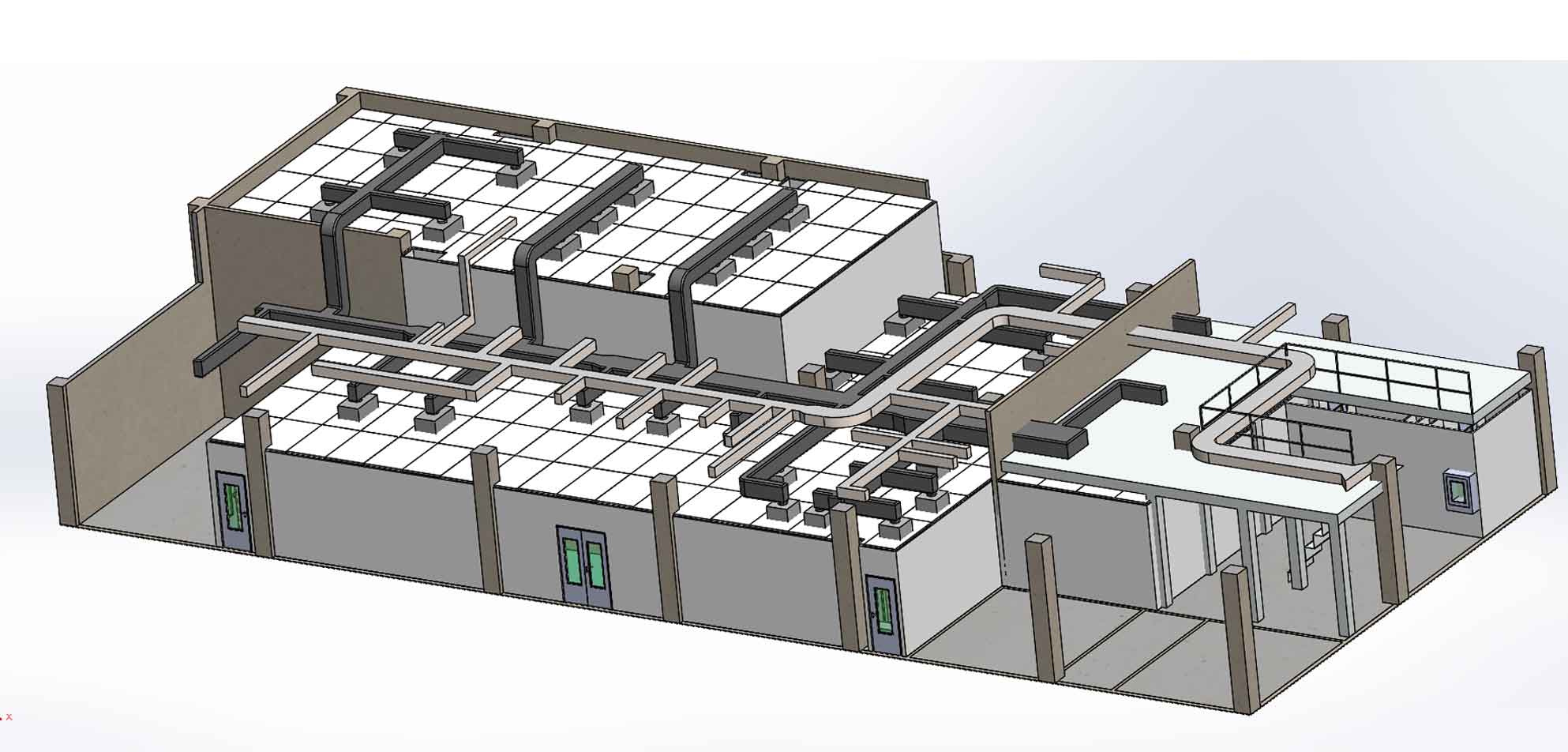

Pre-engineered design: Provides 2D layouts and 3D CAD models for precise planning

Factory-prefabricated modules: Significantly reduces on-site installation time

Wide cleanliness range: Supports Class 1 to Class 100K (ISO 3 to 8)

Intelligent control system: Customizable automation solutions

Transparent visibility: Large observation windows facilitate daily management and client visits

By choosing modular cleanrooms, customers benefit from faster delivery, lower costs, and greater flexibility compared to traditional construction methods.

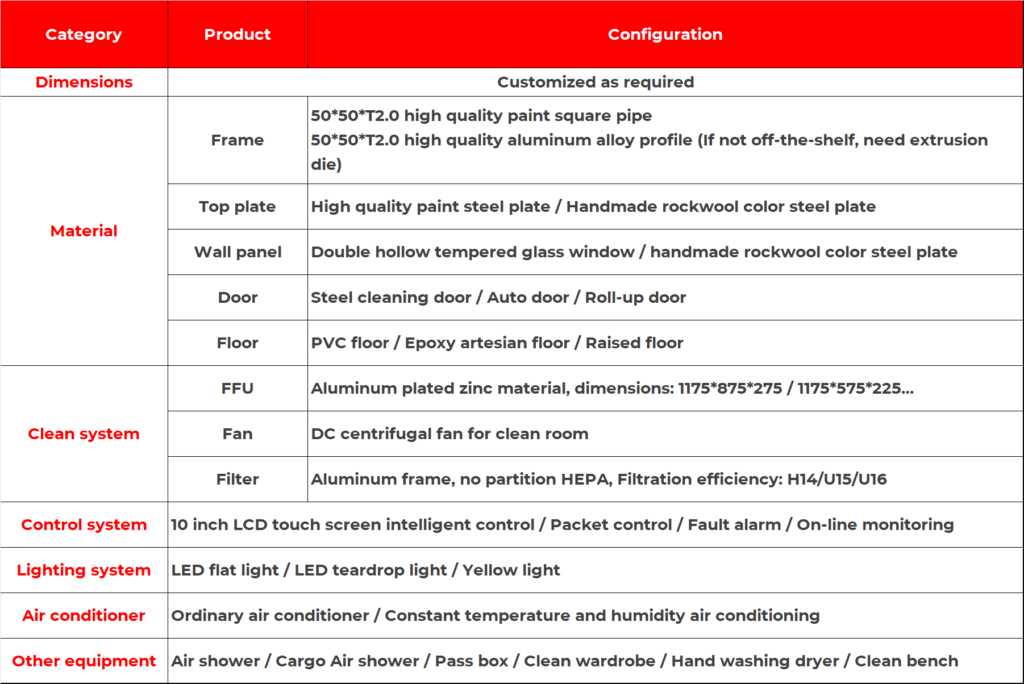

Confirguration Options

Customers may refer to the configuration table on the right to select their preferred cleanroom setup based on actual requirements.

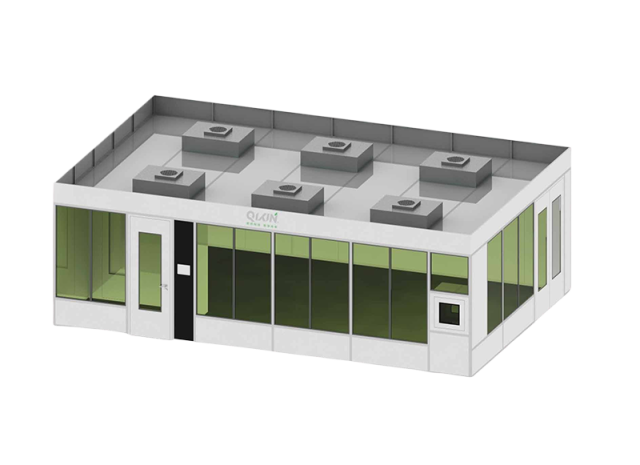

Fresh Air Series

Technical Parameters

Cleanliness: Class 1~100K

Temperature & Humidity: Uncontrolled (relies on external environment)

Key Features

100% fresh air design, no air recirculation, preventing cross-contamination

Low-cost modification, compatible with existing HVAC systems

High-efficiency filtration (HEPA/ULPA) ensures localized cleanliness

Applications

Retrofitting projects: Upgrading cleanliness in specific zones within large workshops (e.g., automotive, electronics assembly)

Budget-sensitive or environments with no strict temperature/humidity requirements

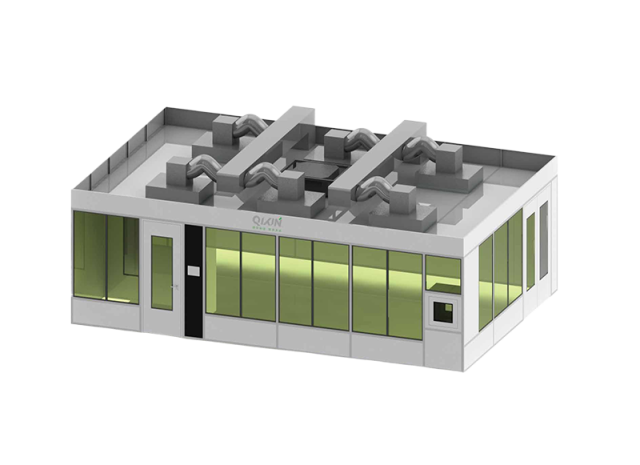

Comfort-Optimized Series

Technical Parameters

Cleanliness: Class 1~100K

Temperature: Controlled (±1~2°C)

Humidity: Uncontrolled

Key Features

Independent temperature control for improved operator comfort

Flexible configuration, suitable for new builds or standalone spaces

Energy-efficient design (optional partial air recirculation)

Applications

New cleanroom construction (e.g., pharmaceutical packaging, precision manufacturing)

Scenarios requiring balanced cleanliness and temperature control without humidity regulation

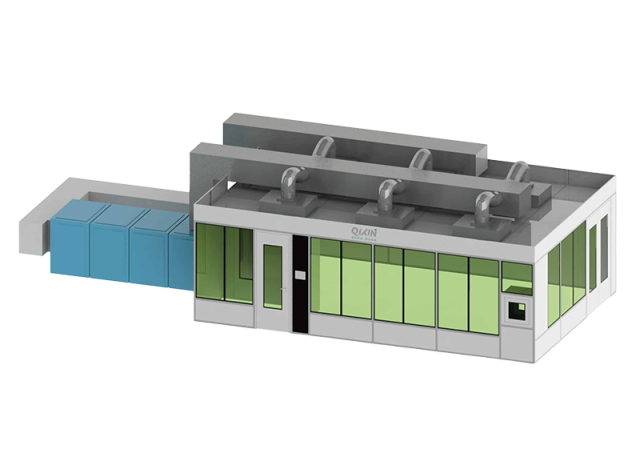

Constant Temperature & Humidity Series

Technical Parameters

Cleanliness: Class 1~100K

Temperature & Humidity: Fully controlled (±0.5°C, ±5% RH)

Key Features

High-precision environmental control for process stability

Fully enclosed air handling system (fresh air + recirculation synergy)

Strong anti-interference capability for demanding environments

Applications

High-sensitivity industries: Semiconductor production, biolabs, optical device manufacturing

Advanced R&D or mass production requiring long-term stable temperature/humidity conditions

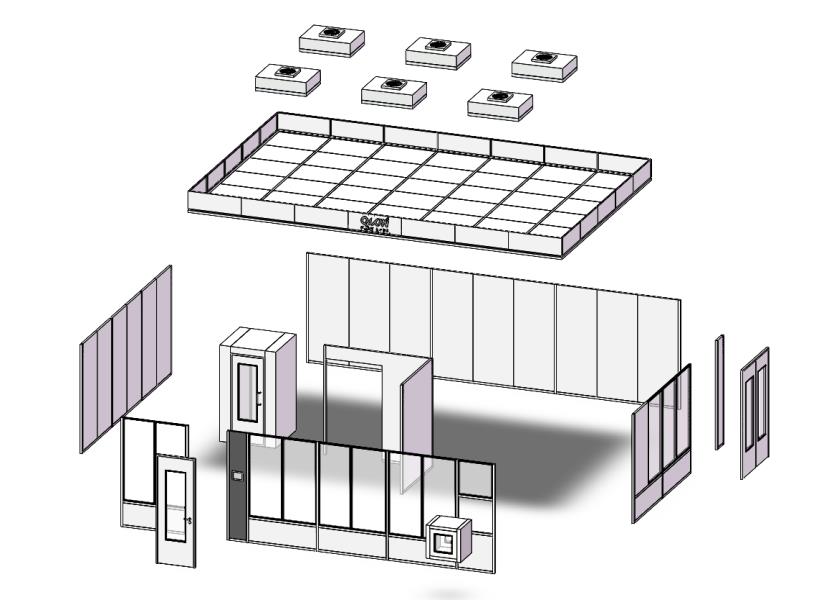

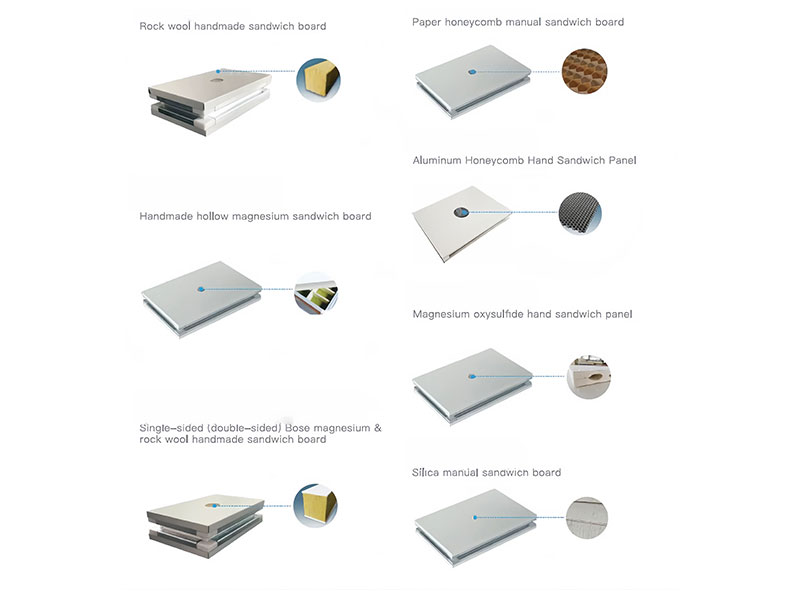

Modular Cleanroom Components

Cleanroom components typically include walls, ceiling grids, and air filtration systems.

Common Modular Cleanroom Applications

Prefabricated Cleanrooms or Modular Cleanrooms offer a convenient and cost-effective solution for creating controlled environments quickly and efficiently. They can be a valuable option for industries that require Cleanrooms for their operations.

Research & Laboratories

Cosmetics & Personal Care

Aerospace

Electronics Manufacturing

Food & Beverage

Medical Device Manufacturing

Automotive Industry

Semiconductor Manufacturing

Cleanroom Construction Made Easy

A short video the highlights the Modular Cleanroom wall systems that KIPRIL offers, along with specifications and common applications for each wall system.

Benefits of Modular Cleanrooms

While flexibility remains a key advantage for the use of Modular Cleanroom systems, there are many reasons to consider modular over conventional construction.

LOWER LIFETIME COST

GREATER SPEED TO MARKET

CLEAN INSTALLATION & MINIMIZED WASTE

FLEXIBILITY TO EXPAND OR MODIFY

REDUCED CONSTRUCTION TIMEFRAME

HIGH REUSEABLE

Get in Touch

Send your enquiry and we will reply you in the first time.

Get in touch with us!